FINE IN-SITU OBSERVATION OF BATTERY INTERIOR WITH XRM

Introduction

The degradation of a battery is caused by a variety of factors. When considered macroscopically rather than microscopically, there are problems such as vacancies, cracks, particle decay, and interfacial peeling. X-ray computed tomography (CT), an internal observation method, can be used for in-situ observation of the inside of a battery without disassembling it. Rigaku’s nano3DX system enables high-contrast and higher-resolution measurement than X-ray micro CTs and can capture and visualize these phenomena.

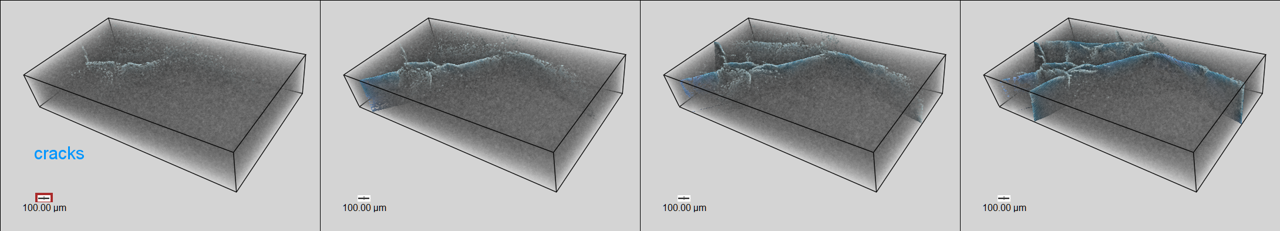

3D rendered X-ray CT images of solid electrolyte. 2.5 micron/voxel

With X-ray tomography, it is possible to non-destructively visualize crack growth within a solid electrolyte during battery operation - providing key insights into potential degradation mechanisms.

More information available in: Visualization and Control of Chemically Induced Crack Formation in All-Solid-State Lithium-Metal Batteries with Sulfide Electrolyte

Misae Otoyama, Motoshi Suyama, Chie Hotehama, Hiroe Kowada, Yoshihiro Takeda, Koichiro Ito, Atsushi Sakuda, Masahiro Tatsumisago, and Akitoshi Hayashi

ACS Applied Materials & Interfaces 2021 13 (4), 5000-5007