IN-SITU OBSERVATION OF STRUCTURAL CHANGES ACCOMPANYING CHARGING-DISCHARGING OF CATHODE MATERIALS OF LITHIUM-ION BATTERIES USING A BATTERY CELL ATTACHMENT

Introduction

Controlling the state of the charge-discharge process is believed to be crucial for extending the life of lithium-ion batteries. Therefore, it is not enough to simply observe the electrode structure in the 100% charged and discharged states, and there is a need to carry out in-situ observation of the relationship between depth of charge, depth of discharge, and electrode structure. However, if materials are removed once from sealed batteries, the materials will react with the atmosphere, and the charge-discharge state will change due to the peeling of electrodes. Thus there is a risk of the material changing into another structure. As a result, with previous methods, it was difficult to observe changes in materials accompanying charging-discharging via an X-ray diffraction measurement. However, with batteries made using a battery cell attachment, X-ray diffraction can be performed simultaneously with charge-discharge testing. Thus it is possible to carry out an evaluation by directly relating changes in the state of samples to charge-discharge characteristics, without performing any additional work on the materials subjected to charge-discharge testing, such as opening seals or peeling electrodes.

Measurements and Results

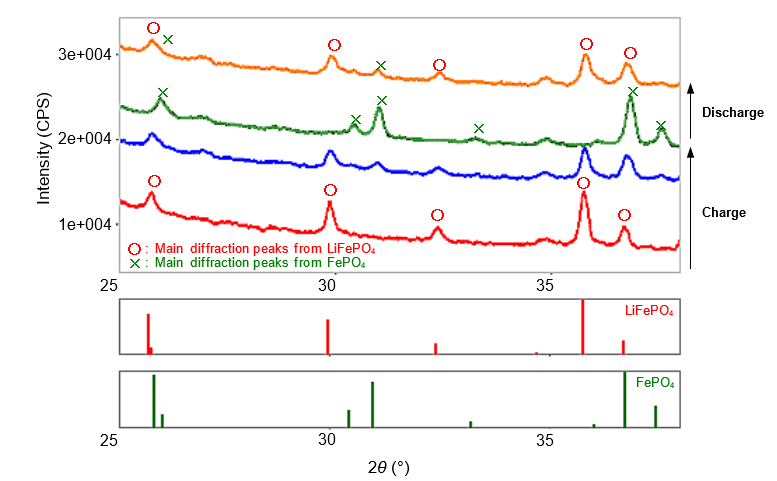

Changes in diffraction patterns in the charge-discharge process of LiFePO4, an olivine-type cathode material for lithium-ion batteries, were observed by using a battery cell attachment. As shown in Fig. 1, in the charging process, the diffraction line intensity decreases for LiFePO4 (the starting material) as the number of charges increases, and the appearance of the diffraction lines corresponding to FePO4 confirmed that LiFePO4 underwent a phase-change to FePO4 during the charging process. Conversely, it was confirmed that FePO4 underwent a phase change to LiFePO4 in the discharge process.

Fig. 1: Phase changes in LiFePO4 accompanying charge-discharge

Samples provided by: Dr. Tatsuya Nakamura, University of Hyogo

Recommended equipment and software

► Automated Multipurpose X-ray Diffractometer SmartLab SE

► Automated Multipurpose X-ray Diffractometer SmartLab

► Battery Cell Attachment

► High-resolution and high-speed 1D X-ray detector D/teX Ultra250

RIGAKU RECOMMENDS

SmartLab