OPERANDO MEASUREMENT OF LI ION BATTERY POSITIVE ELECTRODE USING 2D DETECTOR

Introduction

Lithium-ion secondary batteries are widely used in small portable devices such as mobile phones. Research and development of lithium-ion batteries for use in automobiles and larger machines is an active field. To develop lithium-ion secondary batteries with high capacity, high stability, and long life, it is essential to evaluate the stability of the positive electrode material during the charge/discharge process. Operando X-ray diffraction measurements using an attachment that reproduces the charge/discharge environment and a 2D detector that can perform high-speed measurements enables detailed observation of crystal phase changes while a battery is in use, making it suitable for studying battery performance and life.

Measurements and Results

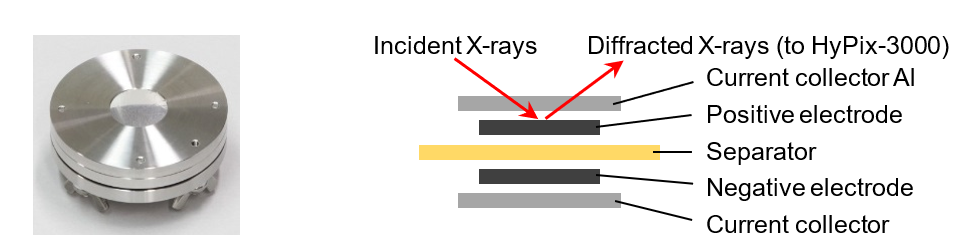

X-ray diffraction measurements of the positive electrode material during high-speed charging and discharging were carried out with a battery cell attachment and a HyPix-3000 2D detector on a SmartLab X-ray diffractometer. Figure 1 shows a picture and an illustration of the cross-sectional structure of a battery cell attachment. The positive electrode material was LiMn1.5Ni0.5O4. Measurement using an exposure time of 15 seconds was repeated while charging/discharging the electrode at a charge and discharge rate 1C = 132 mAh/g. Changes to the X-ray diffraction profile over time were investigated.

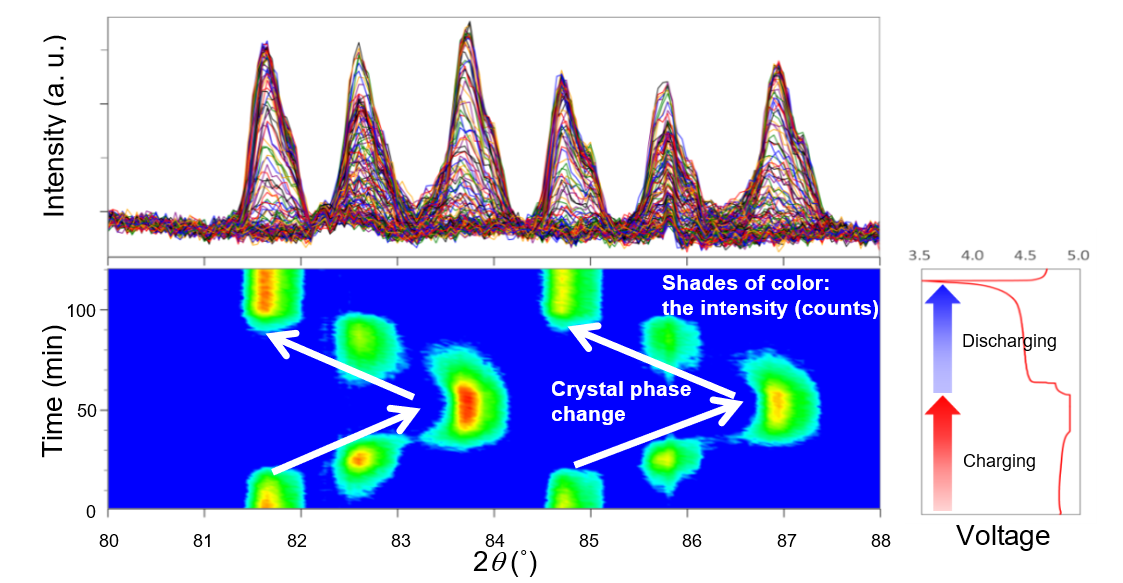

Figure 2 shows the multiple 1D XRD profiles, 2D profile maps, and voltage graphs. Two steps of a two-phase coexistence reaction occurred with charging and discharging. After charging and discharging, the electrode material returned to the same crystal phase as before the measurement started.

Fig.1: Photograph and illustration of the battery cell attachment

Fig.2: Multiple 1D XRD profiles, 2D profile maps, and voltage graphs from repeated charge/discharge of the electrode material.

Recommended equipment

► Automated multipurpose X-ray diffractometer SmartLab

► Hybrid pixel array multi-dimensional detector HyPix-3000

► Battery cell attachment

RIGAKU RECOMMENDS

SmartLab