POROSITY ANALYSIS OF CATHODE-COATED SHEET WITH XRM

Introduction

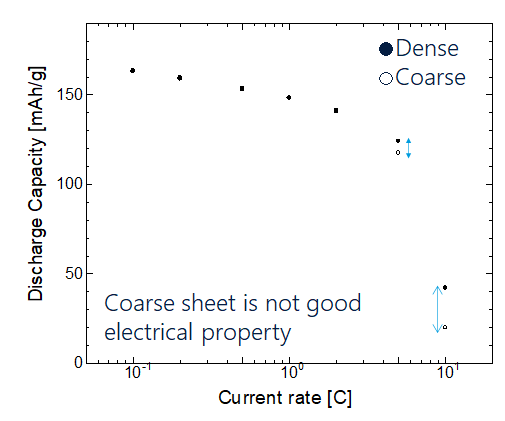

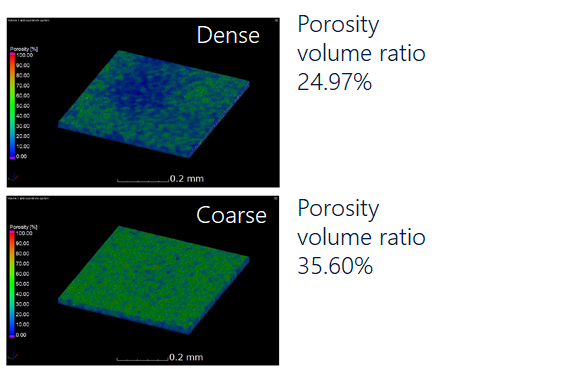

The packing density of a cathode sheet coated on top of an electrode has been found to be related to capacity degradation during the discharge/charge process. As such, the direct analysis of packing density for coated cathode sheets becomes a critical quality test for assessing future battery performance. In the study presented below, the coarseness and fineness of the electrode sheet was analyzed using a high-resolution nano3DX CT imager. From the 3D images, the volume ratio of the vacancies could be calculated and hence density and porosity of the sheet. For cathode coating sheets observed to have a coarser texture, the study determined that the discharge capacity reduced much quicker with discharge rate.

Variations of discharge capacity with current rate for coated cathode sheets

Different porosity for coated cathode sheets after charge-discharge cycles

Samples Provided by Prof. Nakamura who is in Hyogo prefecture university

RELATED PRODUCTS

nano3DX