X-RAY COMPUTED TOMOGRAPHY (XCT) FOR BATTERY

X-RAY CT (XCT)

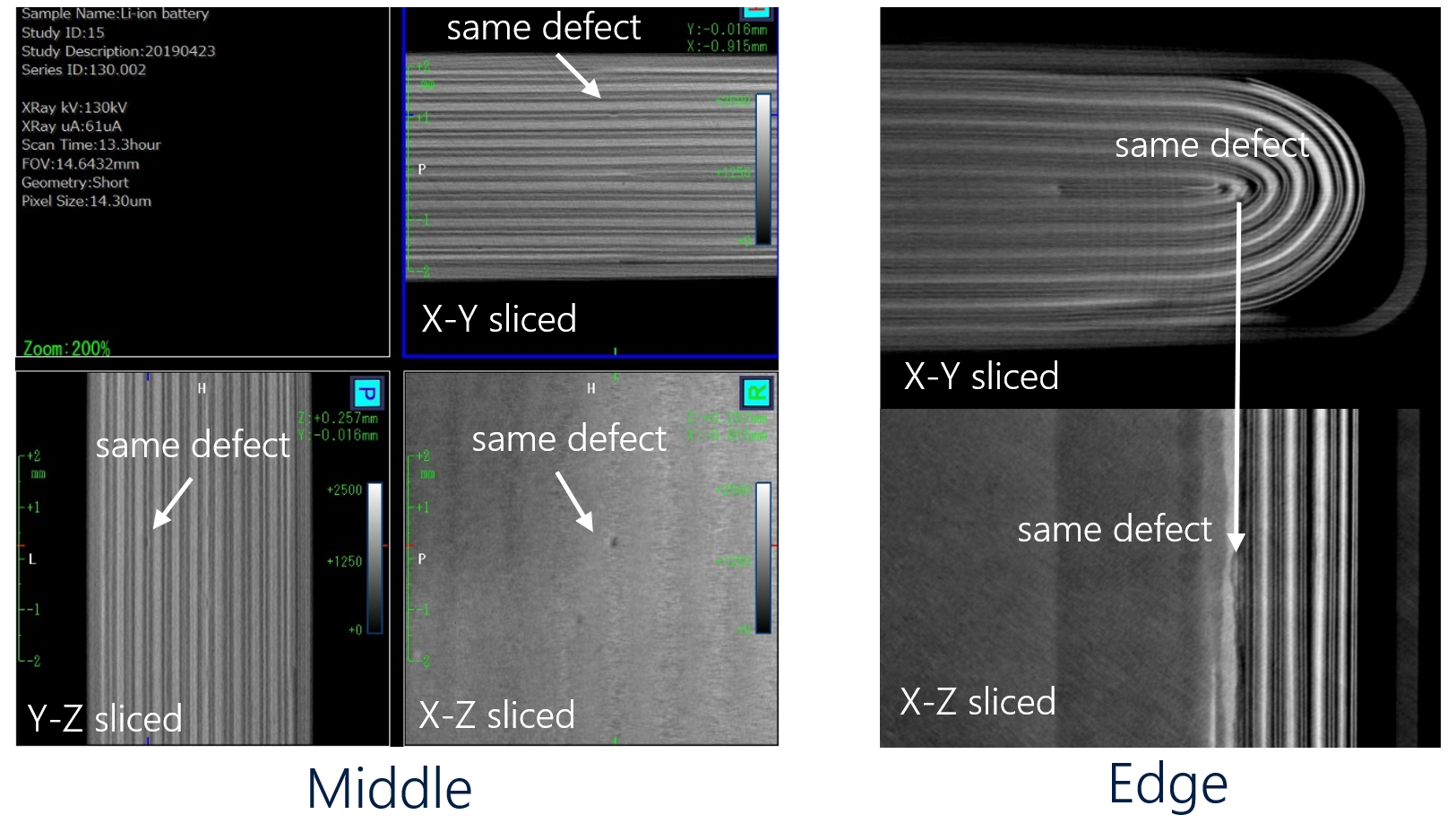

What is X-ray CT? X-ray computed tomography (CT) is a technique to image objects in 3D non-destructively. For example, you can study the internal dimensions of 3D printed objects or voids and cracks in molded parts. Failure analysis of battery products is needed to understand product defects. X-ray CT is effective for failure analysis of multilayered battery cells used for battery products without disassembling them.

X-ray CT images of battery interior

How XCT has evolved: The first commercial CT scanner became available in the ’70s. However, the technique was always used mainly for medical purposes and not so much for materials science and metrology, because we never had good enough analysis tools or fast enough computers to deal with GB size images and produce quantitative analysis results. Then, it all changed in the last several years. Today’s workstations can handle GB size images with no problem, and we can use sophisticated image processing algorithms such as Deep Learning to segment images into multiple phases and analyze their quantitative properties. With those advancements, X-ray CT will play a greater role in materials research in the coming years.he headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

NON-DESTRUCTIVE 3D IMAGING (step by Step)

- X-ray projections are collected from different angles by rotating the sample or the X-ray source and 2D detector.

- The collected 2D projections are reconstructed into a 3D volume by the back projection or other reconstruction methods.

- X-ray CT is an X-ray absorption contrast imaging technique, and X-ray energy needs to be optimized for each sample to maximize the absorption coefficient contrast.

- The magnification geometry and X-ray source and detector types are also optimized for the best resolution.

- The sample geometry is selected based on the type of experiment, the sample-rotation for high-resolution, and the sample-stationary type for in-vivo or in-situ experiments.

- Rigaku nano3DX is optimized for submicron resolution, high-contrast, and fast scans of soft materials.

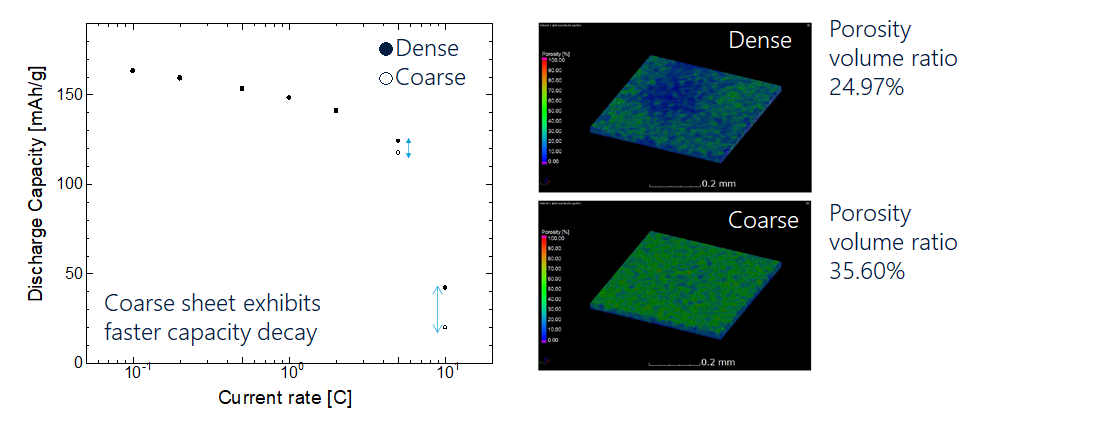

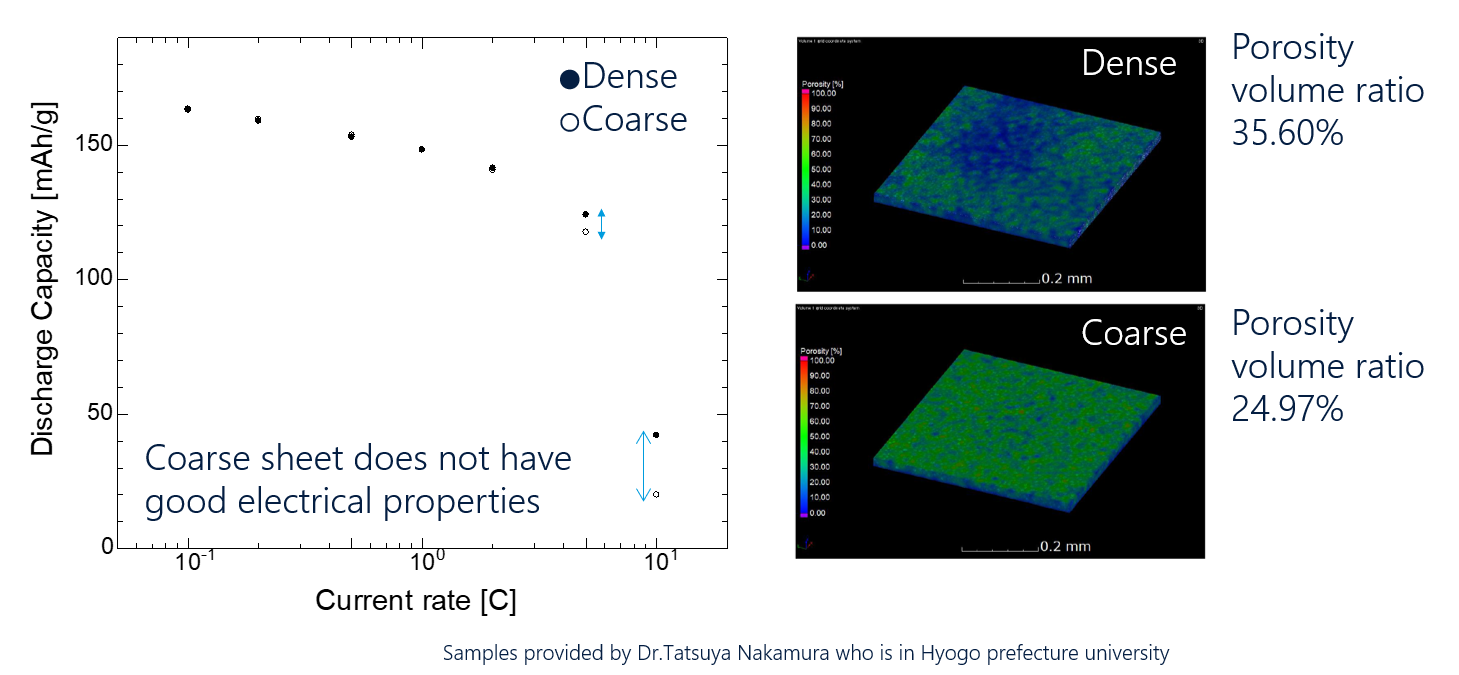

Different porosity for coated cathode sheets after charge-discharge cycles