X-RAY FLUORESCENCE (XRF) FOR BATTERY

MEASURE ALMOST ANY ELEMENT IN ALMOST ANY MATRIX

-

Indispensable to both R&D and quality assurance (QA) functions, our advanced and unique Wavelength Dispersive X-ray Fluorescence (WDXRF) products are routinely used to analyze products from cement to plastics and from metals to food. Not only found in traditional manufacturing industries, but XRF is also a key elemental analysis technique for high-tech semiconductor devices and battery research.

-

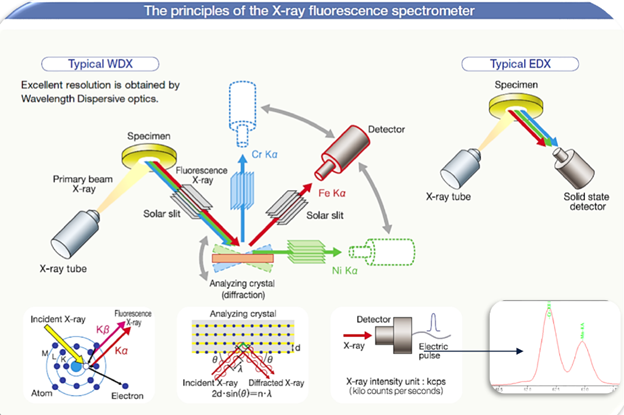

Rigaku offerings range from high power, high-performance wavelength dispersive WDXRF systems, for the most demanding applications, to a complete line of benchtop energy dispersive EDXRF and WDXRF systems.

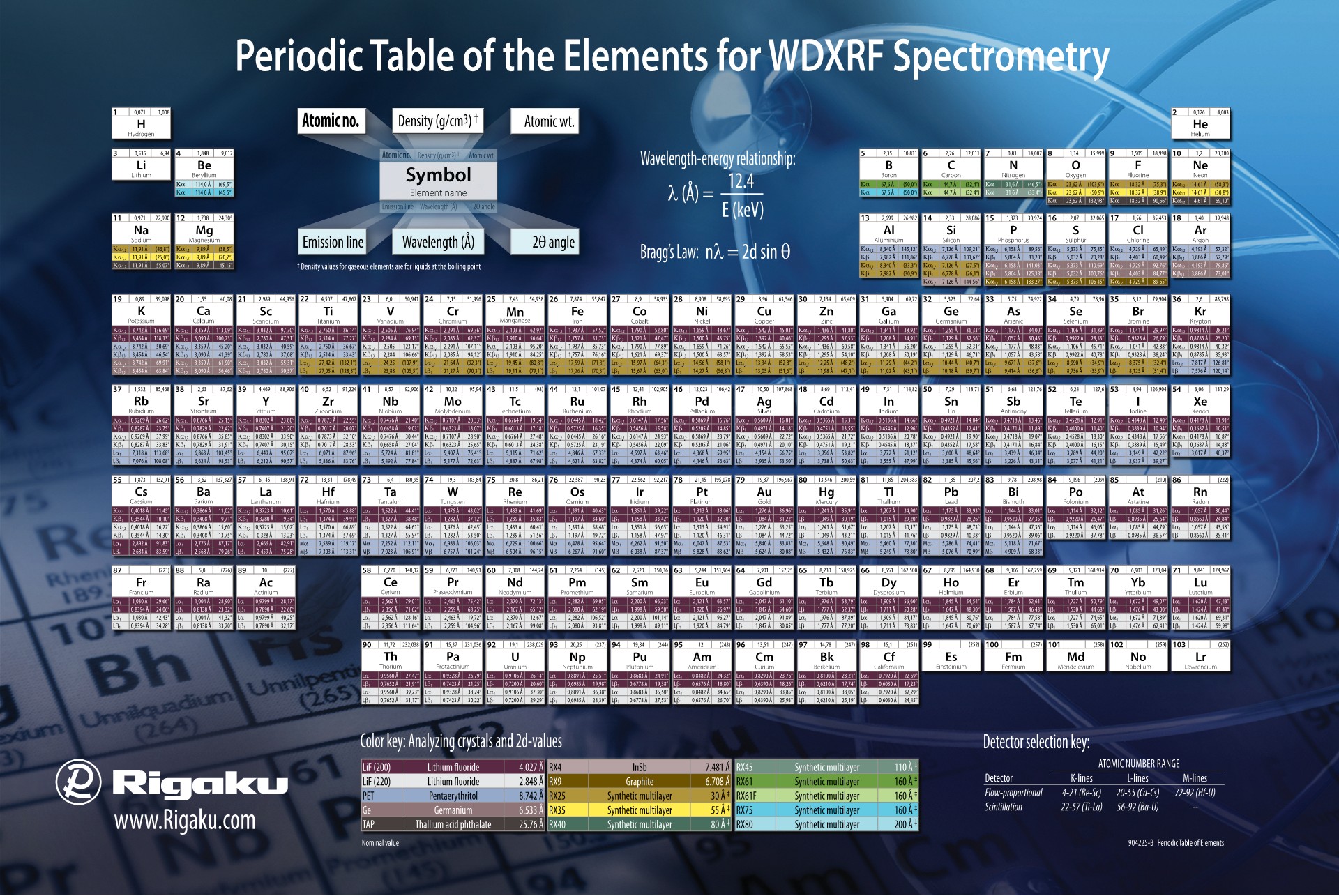

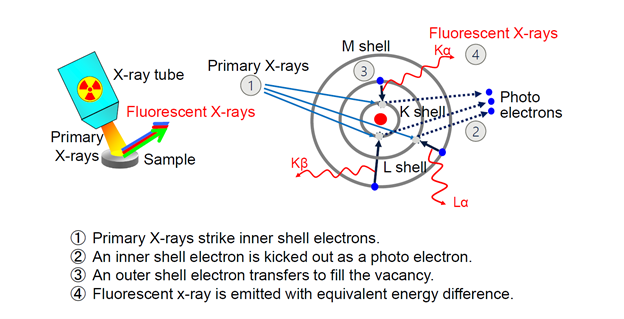

X-RAY FLUORESCENCE (XRF)

What is X-ray Fluorescence? X-ray fluorescence (XRF) provides one of the simplest, most accurate, and most economical analytical methods for the determination of the elemental composition of many types of materials. Indispensable to both R&D and quality assurance (QA) functions, our advanced and unique WDXRF products are routinely used in traditional manufacturing industries (e.g. cement, plastics, metal, food) and in high-tech materials development (e.g. silicon devices and batteries). Rigaku offerings range from high power, high-performance wavelength dispersive WDXRF systems, for the most demanding applications, to a complete line of benchtop energy dispersive EDXRF and WDXRF systems.

RELATED APPLICATIONS FOR BATTERY RESEARCH

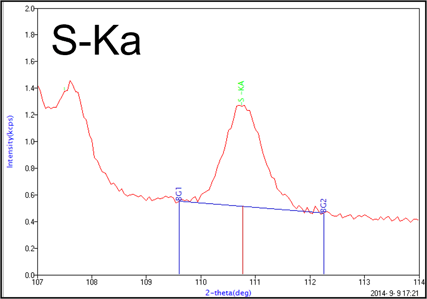

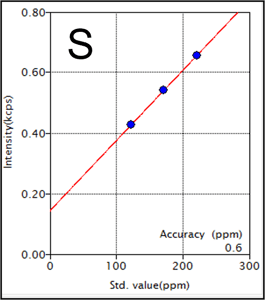

Elemental testing of the various components of the battery (i.e. raw materials, metal caps, battery nails, etc.) can be accomplished using WDXRF. For example, the metal caps can simply be poured into a sample cup and analyzed directly for the low-level impurities of S and Cl to prevent corrosion.

Sulfur peak during WDXRF analysis

Sulfur calibration curve on WDXRF

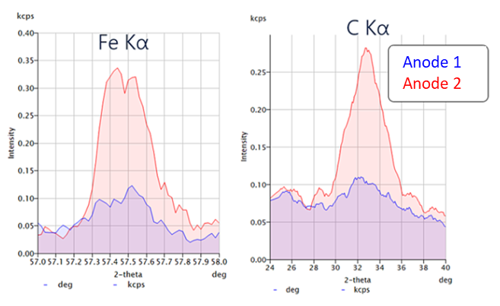

Si-ANODE RAW MATERIAL: The source of pure Si for anode material in lithium-ion batteries is often obtained from semiconductor waste. However, the impurities from this material need to be limited and well-characterized as they may significantly affect performance.

Fe and C intensity comparison between two anodes.

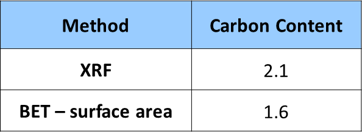

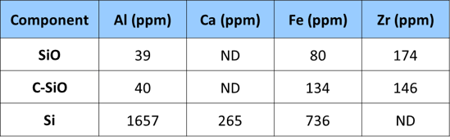

IMPURITIY CONTENT OF Si-ANODE: Impurities such as Al, Ca, Fe, and Zr are easily detected at the ppm concentration levels using semi-quant analyses. To optimize electrical conductivity, the Si-anode material is coated with carbon. XRF can be used to analyze for the carbon content which is comparable to BET (surface area) methods.

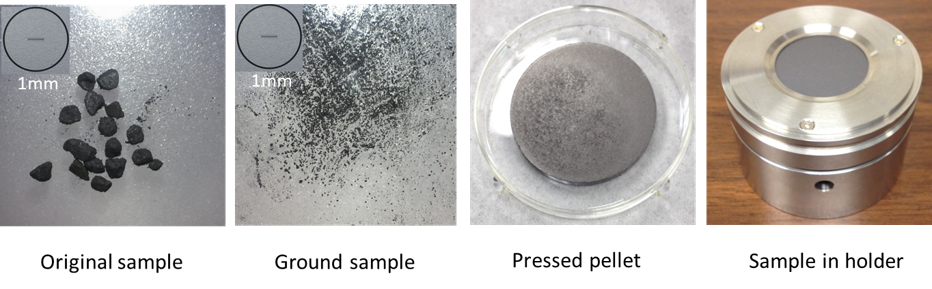

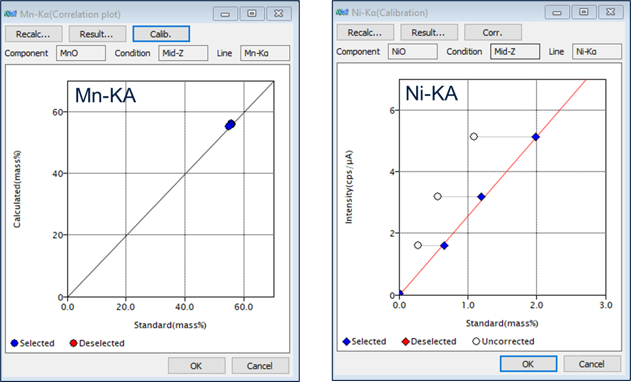

PARTICLE SIZE: The key to accuracy is the reduction of the particle size for MnO and NiO powders. Homogenous sampling ensures accurate and repeatable results.

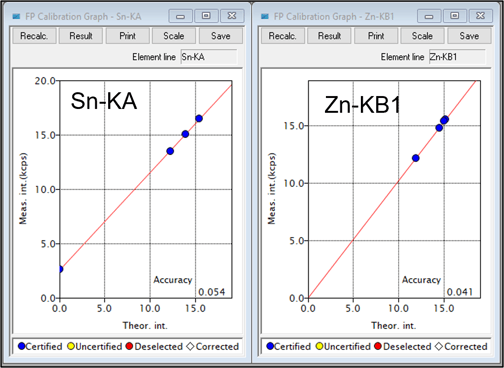

CALIBRATION CURVES: Linear range of graphite containing both MnO and NiO shows good correlation > 0.9999. Direct elemental analysis by XRF can give extremely accurate and precise results without the need to digest samples as required by ICP.

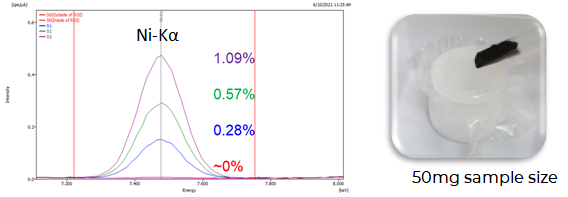

SPECTRAL SCANS: Scans of graphite containing NiO demonstrates good sensitivity with samples as small as 50mg.

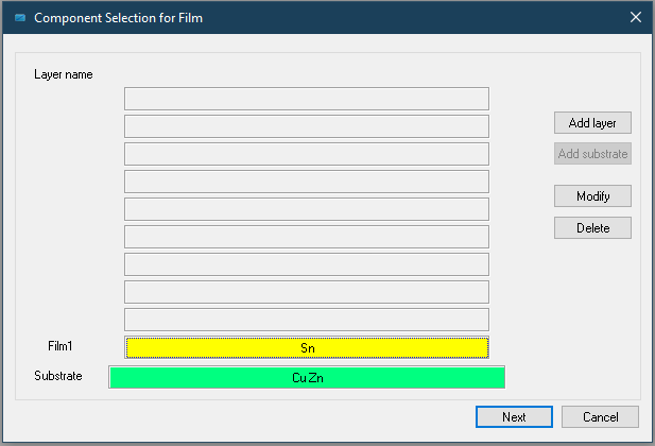

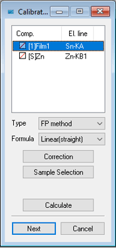

BATTERY NAILS: Both alloy composition and metal coating weights can be achieved with one direct analysis using a thin film model application.

THIN-FILM MODEL: Calibrations are made using various coating weights as well as core alloy compositions through the use of the Thin Film model in Rigaku’s ZSX Guidance software.